Mash or Pellet

Author: Jean-Jacques Trevidy

Publicattion: Hubbard Europe - This article evaluates the options of mashing or pelleting broiler feed, and like many choices the broiler producer has, the answer is dependant upon a number of factors.

Date: 08-04-2005

Introduction

Mash or pellet? The decision is not straightforward, because one must take into account numerous factors together with the complex interactions involved in the feed digestion process. The important factors:

- Genetic evolution and broiler feeding behaviour.

- Feed presentation; feed factory technology; manufacturing costs.

- Housing conditions, management, and health status all have a significant impact on digestion process efficiency and stability,

- digestion process efficiency and stability, Law and regulations with respect to consumer's protection, restriction in the use of antibiotics, growth promoters, and coccidiostats.

- Production conditions vary according to the country, and different technical solutions may lead to good techno-economical results:

For instance in Northern Europe (UK; Holland; Denmark), the raw materials are ground very fine to ensure good cohesion throughout the conditioner and expander treatments at 85-90"C. The benefits of this technique are optimised in cases involving very healthy chicks reared on high-level management and biosecurity farms, The technical results are excellent, but the costs are high, in line with the high food safety expectation of the end consumer.

Brazil can produce high quality raw materials (maize and soya bean). Because of its geographical position and climate, farms are scattered, often very simple in design and flock density is low. Feed is mainly in coarse mash form (only 30 % of the total feed produced is pelleted). Between these two examples, there are many ways of achieving the same technical results according to the local technical and economical conditions.

The main factors at stake are highlighted below:

Genetics

Genetic selection has yielded tremendous progress in weight gain. In the 70's-80's when a higher energy feed, in a pelleted form, was made available it helped to better express the real genetic potential of broilers.

Then, as a consequence of faster growth, problems arose that the primary breeders must now take into account in their selection programmes: skeleton disorders (e.g. lameness) and metabolic disorders (e.g. ascites, sudden death). Lately, the tightening of restrictions regarding the use of antibiotics and coccidiostats has given rise to increased incidence of necrotic enteritis.

Practically, the above problems have mainly been addressed through the implementation of lighting programmes. These aim at slowing down the growth while the birds are young, in order to achieve better skeletal and cardiovascular development, that allows them to sustain later compensatory growth and to decrease the incidence of late mortality. However, the gain in growth potential and therefore in broiler appetite has been such that the lighting programmes were eventually unable to give satisfactorily control. This has been even truer in conditions where the minimum light duration was 16 hours and light intensity was high. Growth control in this case was obtained by quantitative restriction, with controlled feeding schedules (e.g. 2 x 4-5 hours). The use of such techniques showed an improvement in feed efficiency because feed was better digested compared to adlibitum feeding on the one hand, and because late mortality was decreased on the other hand. Obviously proper implementation of the above solutions requires an extremely good level of management and housing conditions.

The field observations are confirmed by scientists like P. Siege] and I. Nir. More recently, B. Svihus from Norway showed that a pelleted wheat based feed presented as a mash following pellet grinding, reduces feed consumption and increases starch digestibility. This is in line with results from Leciercq (1988) and Plavnick (1995), which indicated that the pelleting effect was essentially explained by a higher feed intake. Svihus's work seems to show that pellet over-consumption leads to impaired feed efficiency because of an alteration in feed intestinal flow regulation. Indeed the gizzard may not be able to properly play its regulatory role through its grinding activity; satiety and thus hormonal or nervous communication with the intestine may be impaired.

- The practical consequences of this are that:

- quantitative restriction of broilers improves feed efficiency because of better regulation of intestinal feed flow.

- the gizzard plays a major role in the above feed flow regulation, as long as feed particle size remains coarse.

Feed presentation, feed factory technology & manufacturing costs:

Food Presentation

- The energy value of feed or raw materials may vary with type of feed presentation. These have been estimated for the following feed or cereal presentation:

- whole grain cereals added to complementary feed

- cereals or finished feed in mash form

- finished feed in pellet form.

Whole cereal grain is essentially wheat, barley, sorghum (milo) and to some extent whole maize when it is fed to grown birds (more than 30 days of age and / or over 1.2 Kg in bodyweight). Younger birds may be fed broken maize grain.

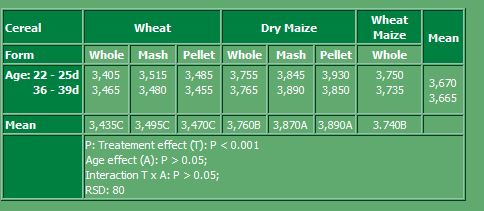

The energy values are stable, regardless of the presentation of the cereal. Cereal AMEN (kcailkg DM)

- In the above trial, wheat and maize are presented in three forms:

- ground for a mash type finished feed

- ground for a pellet type finished feed

- whole grain with a pellet type complementary feed.

Wheat energy value is stable regardless of the type of presentation. Whole grain maize shows a 3% lower value, but this may be due to more difficulty for ingestion of grain.

Mixing whole wheat together with feed, either at the farm or at the feed factory, is a frequent practice in Northern Europe. Most of the time, wheat is added at the farm according to broiler performance and sometimes directly at the feed factory, as the feed is loaded onto the feed delivery vehicle. Wheat addition averages between 15 % and 25 %, according to the broiler slaughter weight.

In the Philippines or in Bangladesh, a 50/50 mix of coarsely ground maize and complementary pelleted or mash feed gives very good results.

Cereals / Mash Feed

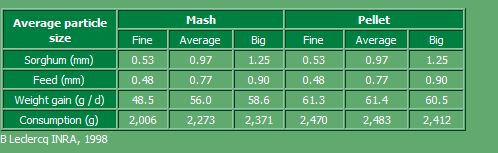

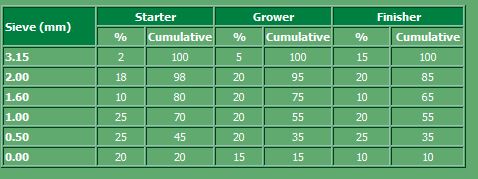

Mash quality is assessed by the size and uniformity of its particles. A positive correlation between the increase in feed particle size and broiler growth has been demonstrated by several authors, including Nir on 0 to 3 week old chicks, and Lecierc on broilers between 22 to 39 days.

Good uniformity of particle size is essential because birds prefer bigger particles. Thus the dominant birds will quickly eat those bigger cereal particles, while the rest of the birds will eat the finer particles. However, particle selection seems to be balanced by the birds since the cereal/concentrate consumption ratio in free choice eating is very similar to that for the whole feed. The improvement in performance with feed particle size and uniformity is explained by the lower energy output birds make when they ingest bigger particles. The number of pecks to eat one given feed amount is reduced when particle size increases.

Being grain eaters, birds have a digestive tract designed to quickly ingest large amounts of feed, that are stored in the crop to be 'hydrated" and 'acidified' by lactic acid secretion before going through the proventriculus. In the proventriculus, hydrochloric acid and pepsin and mucus secretions are increased when feed particle size increases. The gizzard carries out feed grinding, feed impregnation and predigestion of the feed by the secretions from the proventriculus, as well as the regulation of feed in-flow and out-flow. This will have an effect upon three digestive flows: from gizzard to proventriculus; from jejunum to duodenum; from rectum to caeca. The intestinal peristaltic motiiity slows down the feed flow, allows better absorption of the nutrients by the intestinal viol, and helps to stabiiise the intestinal flora.

Pelleted Feed

The positive effects of pelleting are well documented: higher feed density, no feed ingredient separation, better bacteriological quality, easier ingestion, improved growth and FCR. However, these may vary according to the quality of the raw materials, and that of the grinding and pelleting processes.

- The two main physical indicators of pellet quality are

- hardness - measured by pellet resistance to breaking when submitted to external pressur

- durability - measured by the level of "fines" produced during transportation from the feed factory to the farm, and distribution in the feeding system at farm.

Broiler reaction to the above two quality criteria is not easy to assess. In many experiments where better results are obtained with pelleted feed, precise mash characteristics were not given. Indeed, pellets always produce better results when compared to the same fine mash as used to make a good pellet, even more so when the energy level is low. This confirms that the major effect of pelleting dwells in improvement of ingestion.

However, a high energy feed presented either as a coarse mash containing whole grain, or a medium quality pellet because of its fat content, will give very similar results in growth, FCR and fat deposit.

The effect of particle size on growth and consumption of broilers between 21 and 39 days

Broilers may also show high sensitivity to pellet hardness. A hard pellet may be eaten less readily than a softer one, the latter being more likely to yield more fine particles. Still, cereal whole grain ingestion remains easy!

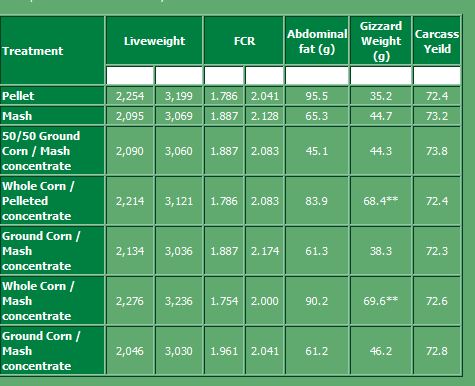

Broiler performance at 42 & 56 days

One must be cautious in practice because field conditions are often different compared to experimental conditions. The positive effect of pelleting is essentially due to the improved ingestion. In reality:

- pelleting improves results for low or medium energy feed, which is easy to pellet. The improvement becomes less conspicuous for high-energy feed that is more difficult to pellet and produces more fine particles throughout the transportation and distribution processes

- when high-energy feed is presented as a coarse mash, or as free choice grain + concentrate, the difference between the results is not as significant as when compared to pellet. This may be the wiser choice to reduce the risk of metabolic diseases.

Feed Factory Technology

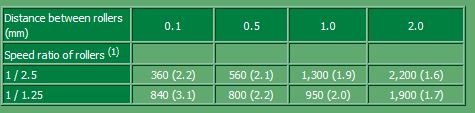

As shown above, a coarse and uniform mash feed is certainly a good solution for broiler production. Coarse mash that may even be used to produce a pellet is an important factor to regulate feed digestion. Feed particle size depends mainly upon grinding. Two types of grinder are available (cylinder grinder and hammer grinder).

"Grinders with fluted cylinders are not designed for heavy production. They are more sensitive to deterioration by foreign bodies, but they are less power consuming and the feed produced is more uniform in particle size.

Grist size (mm) according to roller distance on maize

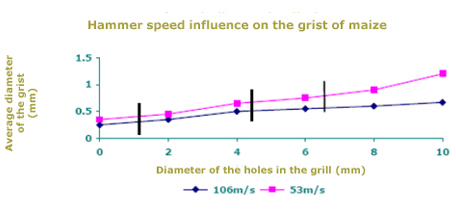

Grinders with hammers are more often used. Grinding is achieved both by contact between feed particles and the hammers and the abrasive effect of the grills, Thus grinding control depends upon two main factors: hammer peripheral speed, and grili mesh size and the percentage of holes. Hammer peripheral speed is a combination of grinder diameter and rotation speed. For one given raw material, the higher the hammer speed, the wider is the distribution range of the feed particles.

- Example of calculation:

- rotation speed = 1,500 RPM (Rotations Per Minute)

- grinder diameter = 0.7 m

- peripheral hammer speed = 0.7 x 3.14 x (1,500/60) = 55m/s

If the grinder runs at 3,000 RPM, the speed is 110 m/s. For poultry feed, 55 m/s is the most frequently used speed. Grinders with variable speed allow adapting speed to the raw materials and to the targets for feed particle size.

Grinder grills: the two important criteria are mesh diameter (from 2 to 10 mm), and the percentage of holes in the grill (from 27 to 52 %). The higher these two values, the higher the average feed particle size and the feed particle size distribution range is.

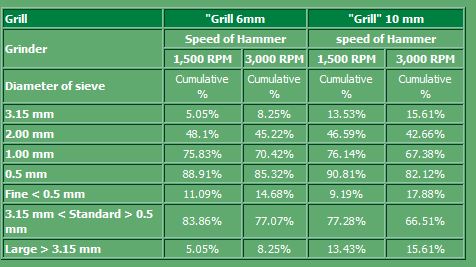

Average grist size of maize (cumulative %) using standard grills

The dispersion of particle size increases with speed of hammer and size of the grill The feed particle size and the average distribution range of the feed particle size must be regularly monitored. Excessive variation is a sign of hammer or grill wear. When blades are worn, the distance between the blade and grill (normally 8mm) is increased. The peripheral feed particle layer therefore becomes thicker and particle ejection is slowed down. The abrasive effect at grill level is increased. Grinder yield diminishes and more fine particles are produced.

In the same manner, worn grills will tend to reject particles back to the grinder instead of letting them out. For most poultry species, the relevant range for feed particle size is -0.5 to 2 mm. Under 0.5mm, particles are less readily ingested, but this size is essentially composed of vitamins and minerals. Above 2 mm, comprises mostly of the cereals, which may give rise to feed particle selection by the birds. Grinders with variable speed improve the uniformity of particle size and diminish the amount of particles outside the desired range. Grinders with 55 m/s speed, together with post-grinding sifting to exclude those particles above 3 mm, give good results when working with larger diameter mesh grills to reduce the production of fine particles.

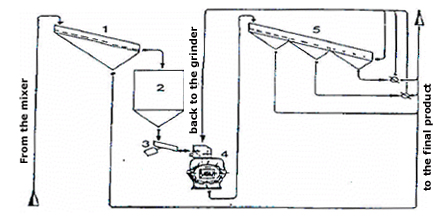

POST SIEVING AND RECYCLING

In hot climates, fine mash is not recommended because of its adverse effect on ingestion. Mash should be coarse. The concentrate part of the feed (premix, minerals and proteins) may be presented as a crumble to reduce the amount of fine particles. When this is possible, it is of real interest to give a crumbled starter feed, made from an initially coarse mash.

The % and cumulative % using standard sieves (AFNOR standards)

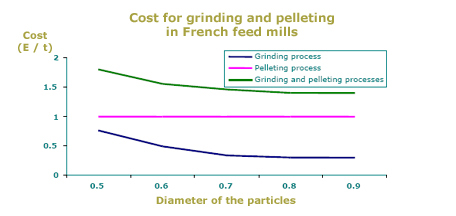

Manufacturing Costs

Power consumption for grinding and pelleting processes, which represents nearly 80% of the total power requirements, is taken into account.

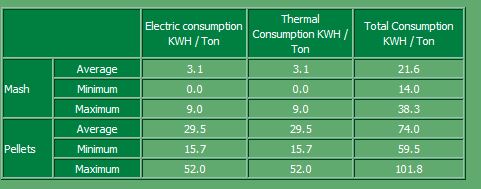

Average power consumption in French feed factories

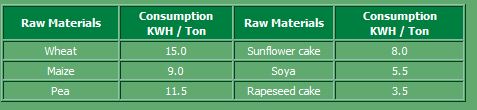

Grinding

Power consumption varies with raw materials and particle size produced

Power consumption and material loss increase with moisture: + 1% moisture =+ 10% more power

Pelleting

This is the highest power consuming operation. Pelleting quality is not easy to assess. Pellet binding must have good adhesion to reduce the production of fine particles during transportation, storage and distribution, yet they must not be too hard in order to avoid possible drops in consumption (Nir). Maize based feed pelleting is more difficult than that of wheat based feed. Several techniques are used to improve pellet binding: finer grinding, the addition of high levels of steam, high temperature (80-85 oC), possible use of an expander, the level of compression (the compression rate of a dye is calculated by: length/diameter=20). These techniques significantly increase power consumption, yet do they provide real guarantees of improved broiler performance?

In reality, comparing mash and pellet on the basis of the same feed formula is often a biased exercise, as the mash should be finer to obtain a good pellet. To compare pellet with a coarser mash, taking into account the additional grinding and pelleting costs, is more relevant.

Housing conditions - Consumer's protection:

Up until recently, farm results and flock health balance was maintained through the use of antibiotics, growth promoters, and coccidiostats. The recent ban on the use of several products, the limited use of others, the longer withdrawal periods prior to slaughter create a more "ecological' environment where the digestive equilibrium is now achieved by acting on feed and on housing conditions.

Housing Conditions

Monitoring temperature, humidity and ventilation is essential to ensure that the intestine and kidneys function correctly. Too high temperature variations, or air draughts in the house, have an impact on chick feeding behaviour. In low temperature and humid conditions, feed consumption is lower, and both gizzard and intestinal viol development are retarded. Such conditions may be met in tropical climates at night when the temperature goes down to 20-250C and or humidity is high. If houses are not heated properly, light is not sufficient, and ventilation is reduced to try to maintain heat, feed consumption is reduced. During the day, the chick wiii over-consume and drink. If the feed is fine, feed digestive flow is quick and feed assimilation is reduced, which results in diarrhoea (with pasted vent). Very rapidly the flock shows impaired uniformity in growth and feathering even when using antibiotics.

Pellets made using fine grinding and high dye temperature increase the viscosity of the intestinal content. This effect is enhanced when saturated fat (palm oil) is added to the formula. In this case, the osmotic pressure of the intestinal content is increased so much that the resorption of liquids normally occurring in the intestine is blocked. Nutrient assimilation in the duodenum-jejunum loop is impaired, favouring bacteria proliferation in the lower digestive tract. This results in a disruption of the microbial balance leading to development of conforms, salmonella and clostridia. The intestinal microbiological balance can then only be restored by using antibiotics, which today has become an undesirable practice.

The above conclusions can be drawn from many different conditions in different countries and they apply not only to young chicks, but also to adult breeders or grown broilers. Most of the experiments conducted in 'organic" type production conditions, with no use of antibiotics or growth promoters or ingredients from animal origin, show that good monitoring of ventilation, humidity, temperature and more generally hygiene, are key points. One may expect further improvement through the use of vaccines against coccidia, salmonella or clostridia.

Feed: manufacturing / formulation

The No 1 criteria in feed manufacturing is raw material selection at the factory entrance, which must conform to both nutritional and microbiological (bacteria and fungi) criteria.

As explained before, pelleting may be a good method to conform to broiler requirements and to obtain the expected performance. When the pelleting process is achieved under good hygienic conditions, it contributes to lower the bacterial load of the feed (enterobacteria, salmonella, E. coli, etc.). However, it may become more risky where the farm technical level is low and the use of antibiotics is strictly limited if not forbidden.

Conversely, a coarse and uniform mash produced from well-controlled raw materials may yield very competitive results. This will be more obvious with higher energy levels. Mash presentation helps steady the digestive process, especially in farms where the technical or health level is not satisfactory, The above conclusions, together with the current concern for a more 'ecological' production system, have led to changes in the feed manufacturing process: grinding speed reduction to 55m/s (1,500 rpm i.s.o. 3,000 rpm), grit] mesh size increase (4 to 6 mm i.s.o. 3 mm), use of wire-type grills with a higher % of holes and the addition of whole grain (wheat) before or after grinding.

Practically, the ideal balance between an expensive good quality pellet and a cheaper good coarse mash is not so easy to find. There are many different economical solutions in between these two options, in response to the complex equation of raw materials, power costs and housing conditions, etc. In one given environment, the best economical balance may even not be that of top class broiler growth.

Mash or Pellet. We hope we have shown that there is no universal answer and that each set of conditions may lead to a different answer.